Prime Scientific - How Intrinsic Viscosity Can Characterize Properties of Plastics

Intrinsic viscosity determination is used in the field of polymer chemistry, which is a chemistry subdiscipline that deals with the synthesis of polymers as well as the analysis of polymer’ structure

The term “plastics” describes a wide range of materials with well-known members such as PET, PBT, PVC and PA to name a few. Plastics are made of polymers which are macromolecules, consisting of repeating units of monomers (Figure 1). The type of monomer and the final size/chain length of the polymer will determine the properties of the material

and therefore the type of application.

Figure 1: A polymer is composed of identical sub-units called monomers

For many reasons monitoring the properties of polymers by determining certain quality parameters is essential in various fields such as research and development, polymer manufacturing, and processing:

▪ Characterizing raw materials and end products

▪ Optimizing chemical and physical properties

▪ Planning polymerization plants

▪ Defining process parameters

▪ Quality control of raw materials and end

products

▪ Avoiding production of faulty batches

One technique which can be used for quality control is dilute solution viscometry. Polymers are diluted in

appropriate solvents and the viscosity of the pure solvent is set in relation to the viscosity of the polymer solution. This procedure yields the relative viscosity, a

basic parameter from which many others can be calculated. The most interesting one is the Intrinsic Viscosity which is related to the molar mass of a polymer.

Theory

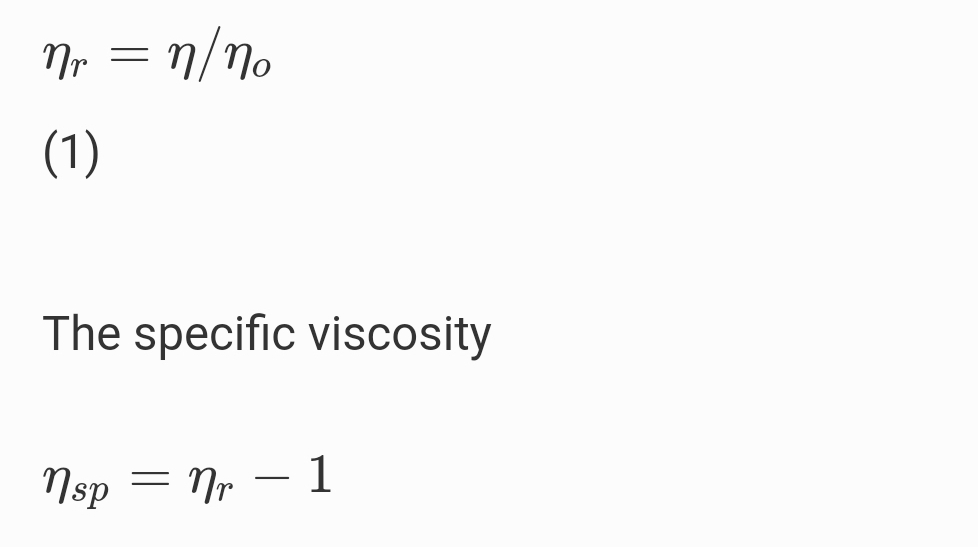

The intrinsic viscosity is an intrinsic measure of the properties of a macromolecule in solution. It does not have the units of absolute viscosity (Poise or (SI units) Pa. s), but rather ml/g. It is measured by determining relative viscosities of solutions, η r where

The IV is determined by the measurement of the viscosity of the dilute solution of the polymer in an appropriate solvent and then correlating it to the molecular weight of the polymer.

Dilute Solution Viscometry (DSV)

An ASTM document describes the test method for the standard test method for dilute solution viscosity (DSV) of polymers. DSV is used for polymers that dissolve completely without chemical reaction or degradation into the solvent and this test can provide an excellent determination of lot-to-lot consistency of the synthesized polymer or can be used to compare molded parts to original resin for determination of degradation from molding.

From the flow time of the pure solvent mixture in a glass, capillary type, viscometer, and the corresponding flow times of known concentration polymers solutions, it is possible to obtain the relative (ηrel), inherent (ηinh), reduced (ηred), and intrinsic [η] viscosities.

Lovis 2000 M Rolling Ball Capillary Viscometer

The Lovis 2000 M is perfectly suited for determining the properties of polymers using dilute solution viscometry as it offers many features making measurements easy and user-friendly:

▪ Polymer software for automatic calculation of all desired polymer parameters

▪ Low sample/solvent consumption reducing the contact with hazardous chemicals

▪ High chemical resistance

▪ Optional combination with sample changers for enhanced throughput

Intrinsic Viscosity measurements of Polybutylene terephthalate (PBT)

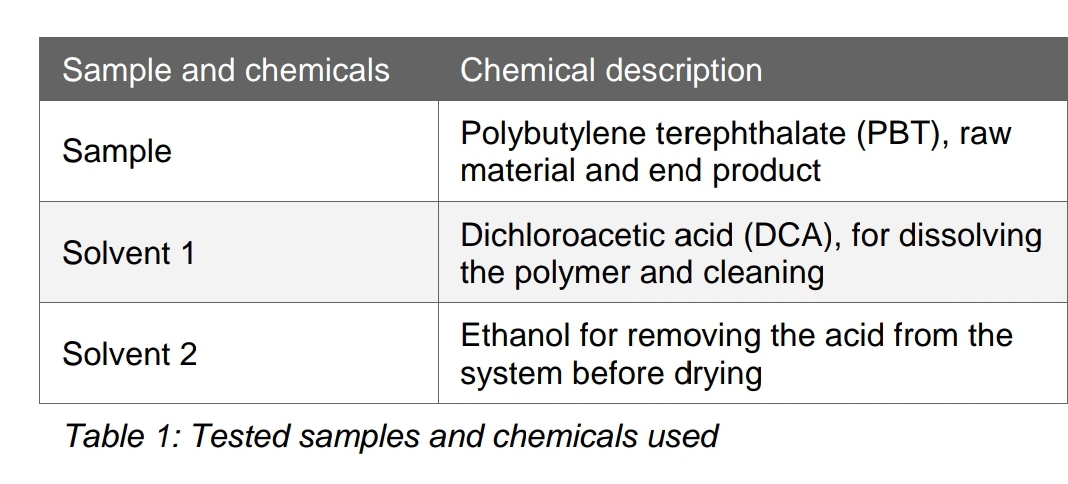

The Intrinsic Viscosity [mL/g] of the PBT raw form and the PBT end product was measured as the end product showed a bad performance in its application (breakage of material under load). Samples and chemicals used are described in Table 1.

Sample preparation

The samples were prepared according to ISO 1628-5, a common test-method for determining the viscosity of thermoplasts. The raw material consisted of small pellets, whereas the end product had to be shredded before testing it, as it consisted of one piece only.

0.250 g of the sample were weighed into a graduated 50 mL flask and the weight was noted down (d = 0.1 mg). A magnetic stirring bar and approximately 25 mL of DCA were added and the flask was closed. For dissolving, the sample was

stirred for 60 min on a hot plate – set to 100 °C – with stirring function. After approximately 60 min the sample was fully dissolved and the flask was removed from the hot plate and cooled to room temperature.

After removing the stirring bar the flask was filled with DCA to a final volume of 50 mL resulting in a final concentration of 0.005 g/mL. To avoid concentration gradients the flask is shaken properly before the measurements. The solvent blank was processed in the same way as the sample. Each of the samples was dissolved three times.

Measurement

Each sample was filled and measured in triplicate: Out of the runtimes of the pure solvent and the polymer solution all polymer parameters were automatically

calculated.

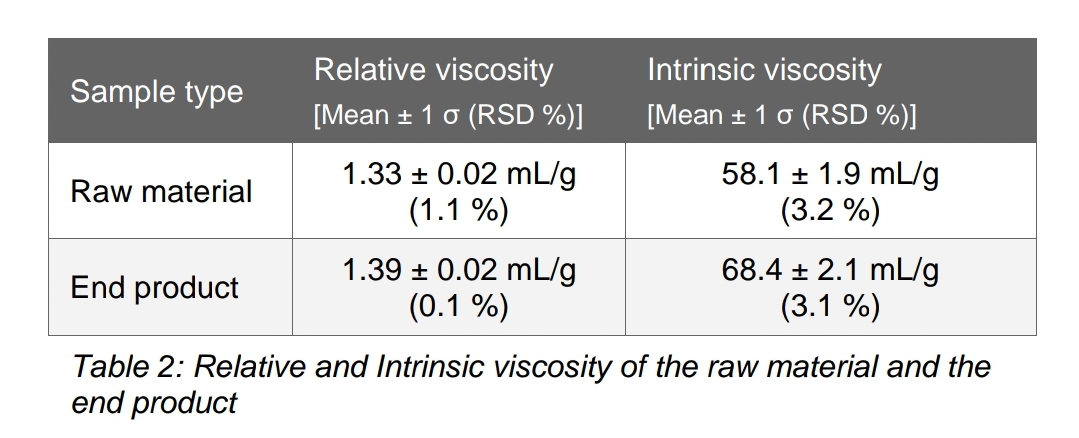

Table 2 displays the results for the raw material and the end product made of PBT expressed in relative and Intrinsic Viscosity [mL/g].

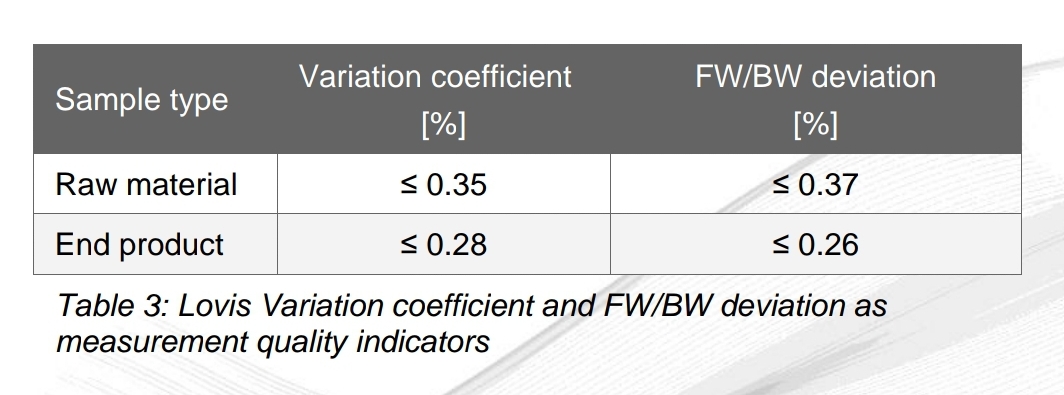

To check the measurement quality two parameters are of interest, namely the FW/BW deviation and the Variation Coefficient (see Table 3).

▪ The FW/BW deviation gives the deviation between the runtime of a forward measurement (e. g. +70° angle) and a backward measurement (e. g. -70° angle).

▪ The Variation Coefficient gives the runtime repeatability in between the measurement cycles.

References

- C72IA033EN-B Polymers | Measuring Intrinsic Viscosity for Optimized Plastic Processing, Anton Paar

- https://wiki.anton-paar.com/sg-en/intrinsic-viscosity-determination/

- https://link.springer.com/referenceworkentry/10.1007/978-3-642-16712-6_283

- https://www.sciencedirect.com/science/article/pii/B9780323358859000011

Prime Scientific

Prime Scientific provides equipment, instruments and other related products and materials. We aim to be a one stop shop for all our customers laboratory needs. Since 2001, Prime has strived to provide the best services and solutions to the scientific community in the region.